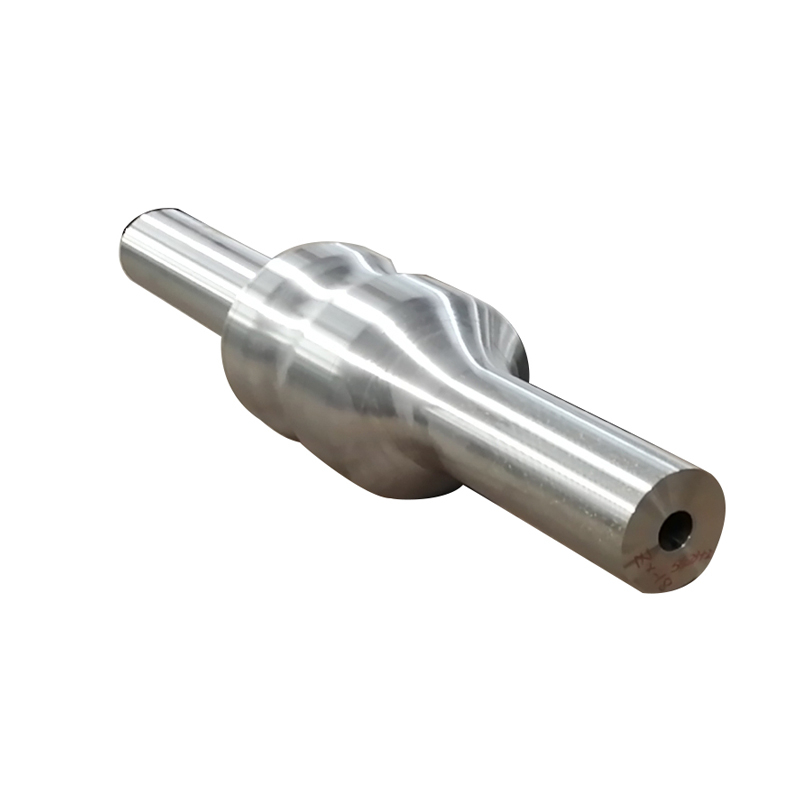

Integral Forged Reamer Body 4145 / AISI 4145H MOD Reamer Body Forging / One-piece Type Reamer Body Forging / Reamer Body Forging with Non-magnetic Material / Reamer Body Forging with AISI 4330V MOD / Reamer Body Forging with AISI 4140

Our Advantages

20-year plus experience for manufacturing;

15-year plus experience for serving top oil equipment company;

On-site quality supervision and inspection.;

For the same bodies of each heat treatment furnace batch, at least two bodies with their prolongation for mechanical performance test.

100% NDT for all bodies.

Shop self-check + WELONG’s double check, and third-party inspection (if required.)

Product Description

WELONG’s Reamer Body – Excellence in Customization, Quality, and Service

With a manufacturing experience of 20 years, WELONG takes pride in producing highly customizable reamer bodies that meet the specific requirements outlined by our customers. Our commitment to quality is unwavering, as we source all raw materials for reamer body production from reputable large-scale steel mills.

The steel ingots used in our process undergo electric furnace smelting and vacuum degassing, ensuring their exceptional purity. To guarantee the highest standards, forging is carried out exclusively using hydraulic or water pressure machines, strictly avoiding the use of hydraulic hammers, air hammers, or rapid forging machines. The forging ratio surpasses the minimum requirement of 3:1, contributing to the durability and reliability of our reamer bodies.

When it comes to grain size, we adhere to a minimum standard of 5 or better, facilitating enhanced mechanical properties. Additionally, cleanliness is paramount, and average inclusions are meticulously controlled according to ASTM E45 method A or C. Our dedication to maintaining the integrity of our products means that no welding repairs are permitted on any forged components.

To ensure flawless quality, ultrasonic testing is conducted following the flat-bottom hole procedure specified by ASTM A587, encompassing both direct and oblique angles. This rigorous testing methodology guarantees the absence of defects and reinforces the reliability of WELONG’s reamer bodies.

Our manufacturing process aligns with the reputable API 7-1 standard, underscoring our commitment to meeting international industry specifications. Prior to shipping, great care is taken to clean the inner and outer surfaces of each reamer body thoroughly. After surface cleaning with a suitable solvent, the reamer bodies are allowed to dry completely before being coated with rust-preventive oil. They are then securely wrapped first in white plastic cloth and then in green-striped cloth, ensuring optimal protection during transportation. Leakage prevention measures are implemented, and every precaution is taken to prevent any damage to the product.

For long-distance shipment, our reamer bodies are packaged in sturdy iron crates, specifically designed to withstand the rigors of sea transportation. This ensures their safe arrival at your destination in impeccable condition.

At WELONG, our commitment extends beyond manufacturing and quality control. We take pride in offering excellent after-sales service, ensuring that our customers’ needs are met with utmost professionalism and efficiency. Your satisfaction is our priority, and we strive to exceed your expectations at every stage.

Choose WELONG’s Reamer Body for an unparalleled combination of customization, exceptional quality, and dedicated service. Experience our expertise, perfected over two decades of delivering reliable and high-performing products to our valued customers worldwide.