In metallurgy, both overheating and overburning are common terms related to the thermal treatment of metals, particularly in processes like forging, casting, and heat treatment. Though they are often confused, these phenomena refer to different levels of heat damage and have distinct effects on metals. This article provides an overview of overheating and overburning, followed by an exploration of their key differences.

Overheating: Overheating refers to a condition where a metal is heated beyond its recommended temperature, leading to a coarse grain structure. In carbon steel (both hypoeutectoid and hypereutectoid), overheating is typically characterized by the formation of Widmanstätten structures. For tool steels and high-alloy steels, overheating manifests as the angular shape of primary carbides. In some alloy steels, overheating can also result in the precipitation of elements along grain boundaries. One of the key concerns with overheating is that the resulting coarse grains can compromise the mechanical properties of the metal, making it less ductile and more brittle. However, in most cases, the damage caused by overheating can be mitigated or even reversed with proper heat treatment.

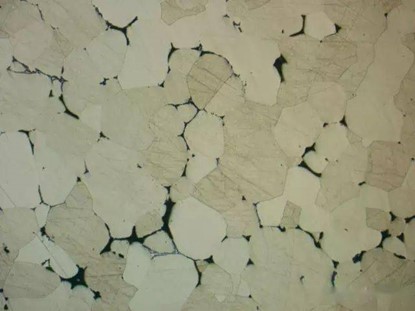

Overburning: Overburning is a more severe condition compared to overheating. It occurs when a metal is exposed to temperatures beyond its melting point, causing the material to deteriorate beyond repair. In severely overburned metals, cracks can form with minimal stress during deformation. For example, when a burned metal is struck during upsetting, it fractures easily, and during elongation, transverse cracks may appear. Overburned areas are distinguished by extremely coarse grains, and the fracture surfaces often exhibit a light gray-blue color. In aluminum alloys, overburning causes the surface to darken, often forming a black or dark gray color with a blistered, pockmarked appearance. High magnification reveals that overburning is typically associated with oxidation and melting along grain boundaries. In severe cases, liquation may occur at the grain boundaries, causing the material to become irreversibly damaged.

Key Differences: The primary distinction between overheating and overburning lies in the severity and permanence of the damage. Overheating causes grain coarsening, but the metal can often be restored to its original condition through proper heat treatment methods. The damage is generally limited to changes in the microstructure and does not lead to immediate catastrophic failure unless the material is subjected to extreme stress.

On the other hand, overburning represents a more critical condition where the material undergoes irreversible damage. The melting or oxidation of grain boundaries means that the metal’s internal structure is compromised beyond repair. Overburning results in brittleness and cracking, and no amount of subsequent heat treatment can restore the material’s mechanical properties.

In summary, overheating and overburning are both related to excessive heating, but they differ in their impact on metals. Overheating can often be reversed, while overburning causes irreversible damage, resulting in a significant loss of material integrity. Understanding these differences is crucial for ensuring that proper temperature control is maintained during metallurgical processes, preventing material failure and ensuring the longevity of metal components.

Post time: Oct-08-2024