The reamer is mainly suitable for formations that are prone to inclination and reduction in diameter, especially in drilling formations that are prone to inclination and reduction in diameter, demonstrating its unique application value.

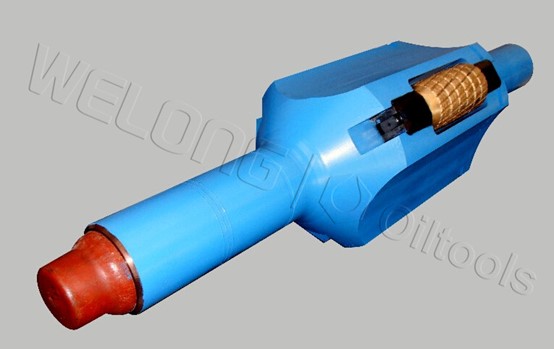

Oil drilling rigs, also known as expanders or reamers, play an important role in oil drilling engineering. Their main function is to expand the borehole while drilling. By installing them in the middle of the drill string with a diameter slightly larger than the diameter of the drill bit, they ensure that the upper reamer simultaneously expands the borehole and repairs the wellbore during the drilling process. The design of this tool takes in account various complex situations that may be encountered during the drilling process, such as changes in formation lithology, temperature and pressure fluctuations, and therefore has specific technical characteristics and advantages:

Applicable terrain: The reamer is particularly suitable for formations that are prone to inclination and diameter reduction. Due to the complex geological structure, these formations are prone to wellbore inclination or diameter changes during drilling. By using an eye expander, the wellbore inclination can be effectively controlled while ensuring the consistency of the wellbore diameter, thereby improving the safety and efficiency of drilling.

Technical features:

Hydraulic reamer: For example, the application of Shengli hydraulic reamer in ultra deep wells has successfully addressed construction difficulties such as high temperature, high pressure, and alternating soft and hard rock formations by adopting measures such as low drilling pressure, small displacement, and selecting high-temperature resistant sealing components, ensuring the smooth progress of eye expander construction.

New type of reamer: With the development of the petroleum industry, the research and development of new type of eye expander has become necessary to cope with complex situations in deep and ultra deep wells, such as dog legs, keyways, and reduced diameters. These new types of eye expanders typically have higher durability and reliability, and can meet the needs of deep well drilling.

Drilling reamer: such as Halliburton’s TDReam™. The drilling reamer reduces the length of the borehole to below 3 feet, saving drilling time and costs, and lowering risks. The design of this tool allows for direct expansion of the borehole during the drilling process without the need for additional tripping steps, thereby improving work efficiency.

Post time: Sep-18-2024