When choosing a stabilizer, comprehensive consideration should be given to materials, models, process quality, product safety certificates, and other aspects.

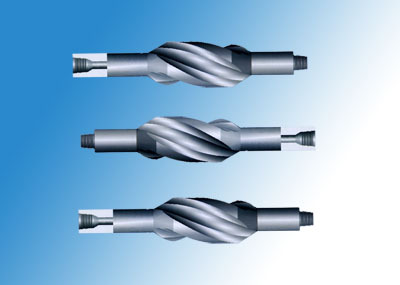

There are various types of stabilizers, including elastic stabilizers, rigid stabilizers, semi-rigid stabilizers, roller stabilizers, tubing stabilizers, sleeve stabilizers, etc. When choosing, not only should the type of stabilizer be considered, but also its material, model, process quality, and product safety certificate should be taken in account. Although the design and structure of the stabilizer are not complicated, its production is not simply steel welding, but involves a series of safety issues. Therefore, when choosing, one should not be tempted by cheapness, but should focus on quality.

l Material: The material of the stabilizer has a direct impact on its performance and service life. For example, MC nylon, as a new type of engineering plastic, has the characteristics of high strength, good resilience, wear resistance and self-lubricating properties, noise absorption and shock absorption, and low friction coefficient. These characteristics have rapidly increased the status of MC nylon in engineering plastics and made it an important material. Compared to metal, MC nylon has lower hardness, does not damage the abrasive parts, and provides a practical way to prevent noise that is superior to metal.

l Model and process quality: The model and process quality of the stabilizer are also important factors to consider when selecting. Different types of stabilizers are suitable for different working environments and conditions, and the quality of the process directly affects the durability and safety of the stabilizers. High quality products will strictly control every aspect of the production process to ensure the performance and safety of the final product.

l Product Safety Certificate: When selecting a stabilizer, it is also necessary to check whether it has the relevant product safety certificate. These certificates are proof of product safety and compliance, as well as an important basis for selecting high-quality stabilizers.

In summary, when choosing a petroleum stabilizer, factors such as the type, material, model, process quality, and product safety certificate of the stabilizer should be comprehensively considered to ensure that the selected stabilizer can meet specific working environments and conditions, while ensuring safety and durability during use.

Post time: Jul-23-2024