Petroleum Drill Bit

The petroleum drill bit plays a critical role in oil drilling, significantly influencing drilling quality, efficiency, and costs. Types of petroleum drill bits include scraper bits, roller cone bits, diamond bits, and PDC bits (polycrystalline diamond compact bits). This article focuses on scraper bits.

Scraper bits were among the first used in rotary drilling, originating in the 19th century and still employed in certain oilfields today. They excel in soft and adhesive formations, offering high mechanical drilling speed and penetration capabilities. Scraper bits are valued for their simple design, cost-effectiveness, and adaptability for custom manufacturing in individual oilfields.

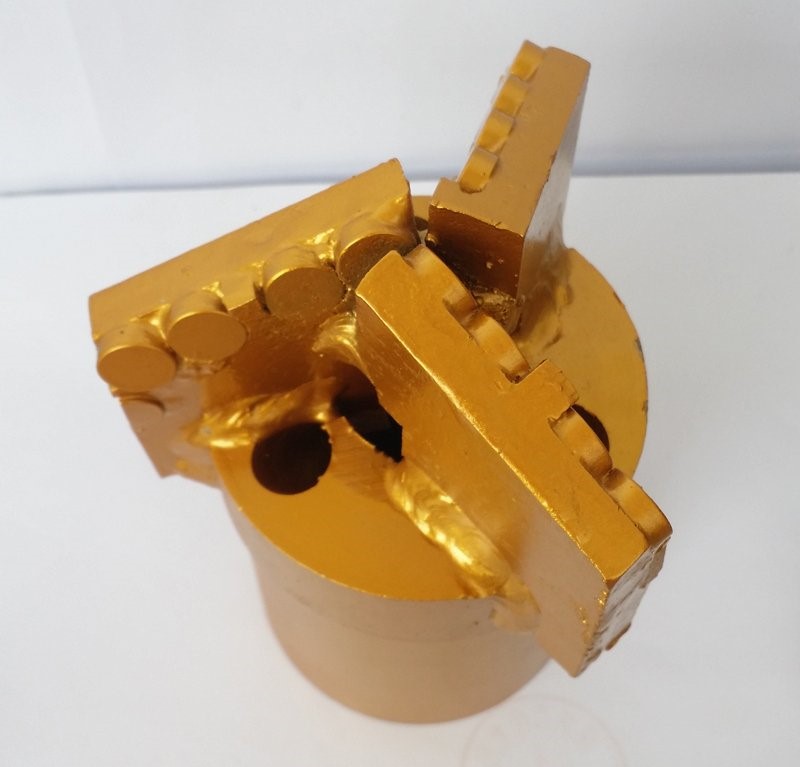

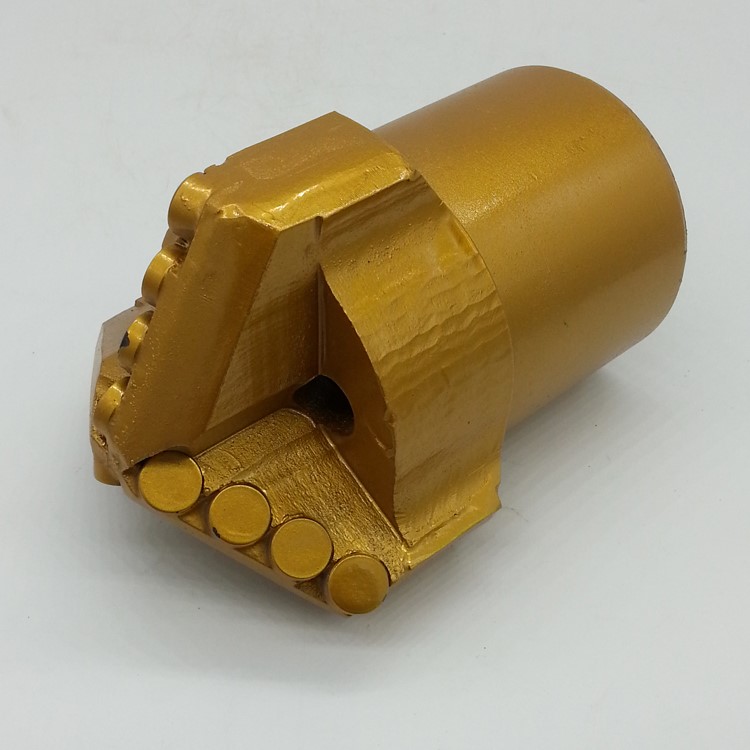

A scraper bit consists of a bit body, scraper blades, nozzles, and a bullnose. The bit body, made from medium-carbon steel, features welded scraper blades and a bullnose at the lower end, with threaded connections at the upper end for attachment to the drill string. Scraper blades, also known as wings, are essential components of scraper bits.

Scraper bits deliver superior performance in soft and adhesive formations. During drilling operations, precise control of drilling pressure and rotational speed is crucial to prevent deviation and blade fractures. Given the high mechanical drilling speed in soft formations and the resulting large volume of cuttings, using high-volume drilling fluid is recommended to ensure thorough cleaning of the borehole bottom and effective cooling of the bit. Moreover, the increased peripheral speed of scraper bit wings can lead to conical wear, requiring careful measures to prevent borehole narrowing and further deviation.

Beyond their excellent performance in soft and sticky formations, scraper bits are also demonstrating advantages in other developmental areas. For example, in high-temperature and high-pressure environments, scraper bits maintain stable performance, ensuring safe and efficient drilling operations. This versatility establishes scraper bits as an indispensable choice in petroleum drilling, whether in traditional oil extraction or in facing the emerging challenges of deep-water and ultra-deep-water regions, underscoring their unique value and application potential.

Post time: Jul-12-2024