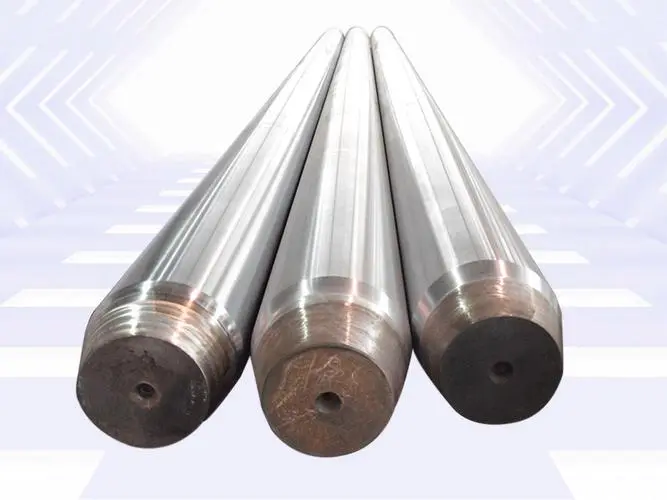

Mandrel is a type of mold component used to form contour surfaces in the pressing direction within a billet or sintered body. It is mainly used for bending metal pipes, which is achieved through the Mandrels of the bending machine. These mandrels are composed of multiple components, including upper templates, lower templates, shear knives, etc., and the bending of metal pipes is achieved through pressure and transmission systems.

Ordinary mandrels can be subjected to heat treatment in box type or well type resistance furnaces, but the process is complex and the heat treatment cycle is 2-3 days long, requiring long-term heating and insulation. During quenching, oil quenching treatment must be carried out, producing a large amount of dust and smoke, and the on-site working environment is extremely harsh; After heat treatment, the workpiece is prone to deformation and bending, and must be straightened on a large tonnage hydraulic press, resulting in high manufacturing costs. The ultra long limit moving Retained Mandrel used in the continuous rolling pipe mill is an indispensable tool for rolling large-diameter seamless steel pipes for oil extraction and transportation.

Retained mandrel is a common type of mandrel on CNC machine tools, which is mainly used to improve machining accuracy and stability in rigid machining processes.

The retained mandrel has the following characteristics

1. Limitation on the strength of the retained mandrel: The so-called “limit movement” refers to the slight movement of the front end of the retained mandrel within a certain range, and then the strength of the Retained Mandrel is limited by the constraint component. This design can avoid excessive movement of the retained mandrel, thereby improving machining accuracy and stability.

2. Suitable for rigid machining: retained mandrels are usually used for rigid machining, such as drilling, reaming, boring, etc. At this point, the retained mandrel will tightly grip the workpiece to ensure stability and accuracy during the machining process.

Post time: Jul-03-2024