In the oil drilling process, the drilling tool system plays a crucial role in breaking rock, drilling into the earth, and extracting oil or natural gas. An oil drilling rig typically consists of a power system, transmission system, work systems, and auxiliary equipment, encompassing eight key systems: lifting system, rotating system, drilling fluid circulation system, transmission system, control system, power drive system, rig base system, and auxiliary equipment system. A drilling rig must be capable of lifting and lowering tools, rotating the drill, and effectively circulating drilling fluid for well washing. Common equipment includes the derrick, hoist, winch, traveling block, hook, rotary table, mud valve (mud valve actuator), and drilling pump (the “eight key components” of the rig), as well as power units such as diesel engines, electric motors, gas turbines, coupling machines, solid-phase control devices, and blowout preventers.

Here’s a detailed breakdown of the key systems in an oil drilling rig:

- Lifting System

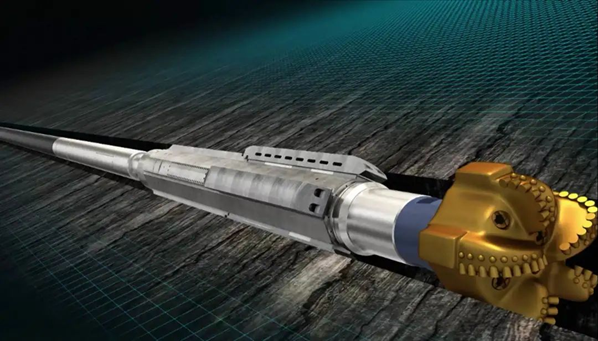

The lifting system is made up of a winch, derrick, hoist, traveling block, hook, and steel wire ropes. The hoist, traveling block, and steel ropes together form the traveling system. The primary function of the lifting system is to raise and lower the drill string, control casing pipe depth, handle downhole complex situations, and assist with lifting heavy objects. - Rotating System

The rotating system consists of the rotary table, mud valve (mud valve actuator), downhole drill string, and powered drilling tools. Its main function is to drive the drill string and drill bits, linking the lifting system and the drilling fluid circulation system. This ensures smooth drilling operations. - Drilling Fluid Circulation System

The drilling fluid circulation system is composed of drilling pumps, surface manifolds, standpipes, mud hoses, mud preparation and purification equipment, downhole tools, and nozzle systems. The system’s primary purpose is to clean the bottom of the well, carry cuttings, and transmit power, keeping the wellbore clean and preventing blockages. - Transmission System

The transmission system connects the power unit to the work machinery through various transmission devices, such as couplings. Its essential function is to efficiently transmit and distribute power to the work units, ensuring smooth operations during drilling. - Control System

The control system consists of various control devices, typically integrated with mechanical, electrical, pneumatic, and hydraulic controls. Mechanical control devices include handles, pedals, and levers; electrical control includes basic components like resistors, relays, and microcontrollers; and pneumatic and hydraulic controls involve cylinders, working cylinders, and other components for precise regulation of rig operations. - Hydraulic Lifting System

The hydraulic lifting system typically uses hydraulic cylinders to raise or lower the derrick. The extension and retraction of the hydraulic cylinder piston rods control the vertical movement of the derrick. The stability of the hydraulic system is critical to the smooth operation of the rig, enhancing efficiency and accuracy during drilling.

The integration of these systems ensures that oil drilling operations are efficient and precise. The safety and reliability of each system are critical to the success of the drilling process, and they work together to achieve the best performance during drilling operations.

Post time: Nov-15-2024