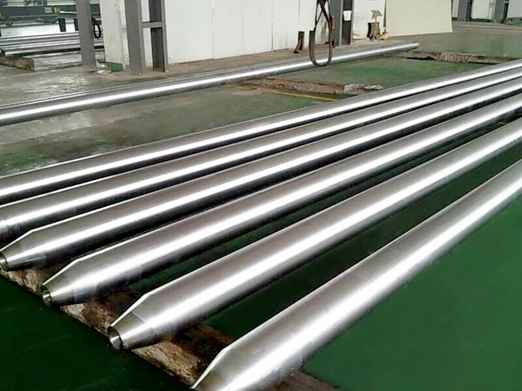

The mandrel is a crucial tool in the production of seamless pipes. It is inserted inside the pipe body, working together with the rollers to form an annular pass, thereby aiding in shaping the pipe. Mandrels are widely used in processes such as continuous rolling mills, cross-roll elongation, periodic pipe rolling mills, piercing, and cold rolling and drawing of pipes.

Essentially, the mandrel is a long cylindrical bar, similar to a piercing plug, participating in the deformation of the pipe within the deformation zone. Its movement characteristics vary with different rolling methods: during cross-rolling, the mandrel rotates and moves axially within the pipe; in longitudinal rolling processes (such as continuous rolling, periodic rolling, and piercing), the mandrel does not rotate but moves axially along with the pipe.

In continuous rolling mill units, mandrels typically operate in groups, with each group containing at least six mandrels. The modes of operation can be categorized into three types: floating, constrained, and semi-floating (also known as semi-constrained). This article focuses on the operation of constrained mandrels.

There are two operational methods for constrained mandrels:

- Traditional Method: At the end of rolling, the mandrel stops moving. After the shell is removed from the mandrel, the mandrel quickly returns, exits the rolling line, and is cooled and lubricated before being reused. This method is traditionally used in Mannesmann Piercing Mills (MPM).

- Improved Method: Similarly, at the end of rolling, the mandrel stops moving. However, after the shell is extracted from the mandrel by the stripper, instead of returning, the mandrel moves forward quickly, following the shell through the stripper. Only after passing through the stripper does the mandrel exit the rolling line for cooling, lubrication, and reuse. This method reduces the mandrel’s idle time on the line, effectively shortening the rolling cycle and increasing the rolling pace, achieving speeds of up to 2.5 pipes per minute.

The main difference between these two methods lies in the mandrel’s movement path after the shell is removed: in the first method, the mandrel moves in the opposite direction of the shell, retracting from the rolling mill before exiting the rolling line. In the second method, the mandrel moves in the same direction as the shell, exiting the rolling mill, passing through the stripper, and then exiting the rolling line.

It is important to note that in the second method, since the mandrel needs to pass through the stripper, the stripper rolls must have a quick open-close function when rolling thin-walled steel pipes (where the reduction ratio of the stripper is at least twice the wall thickness of the shell) to prevent the mandrel from damaging the stripper rolls.

Post time: Aug-07-2024