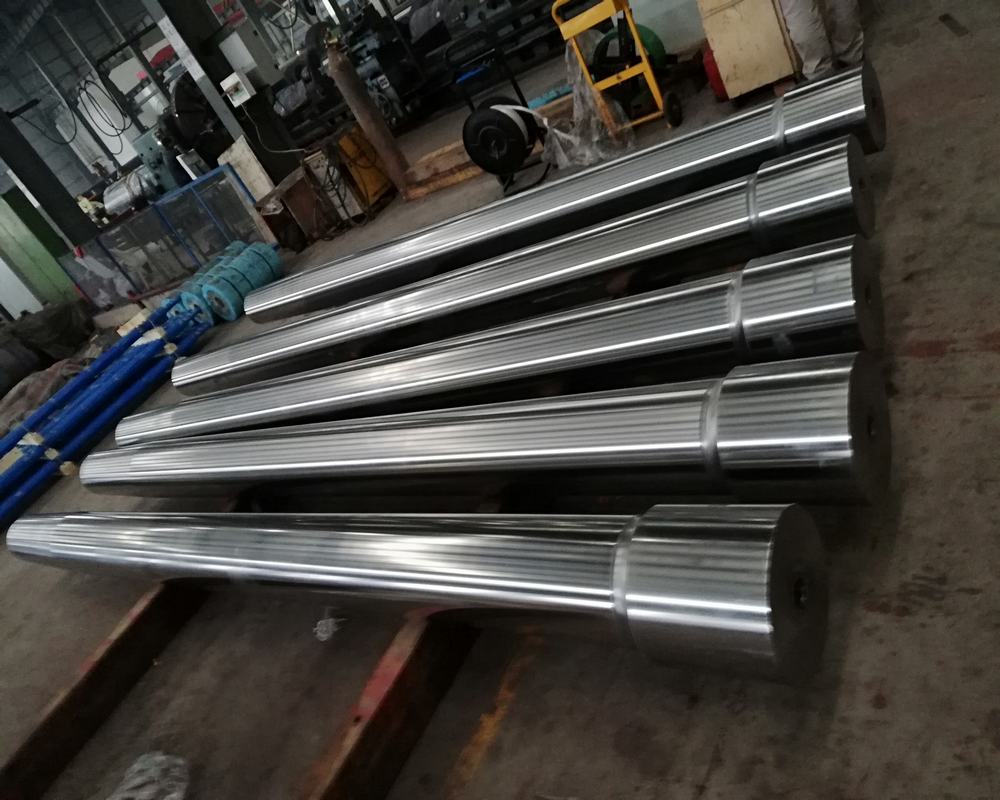

Forged piston rods are renowned for their superior strength and reliability, making them a preferred choice in various industries. One of the primary advantages of forged piston rods lies in the inherent grain structure resulting from the forging process. Unlike cast or machined piston rods, which may exhibit irregular grain patterns and internal voids, forged piston rods possess a refined grain structure that follows the contour of the component. This alignment of grains enhances the shaft’s mechanical properties, including tensile strength, fatigue resistance, and impact toughness. As a result, forged piston rods exhibit exceptional durability and can withstand high-stress applications, making them ideal for critical components in machinery, automotive systems, aerospace equipment, and more.

Furthermore, the forging process allows for precise control over the shape and dimensions of the shaft, leading to superior dimensional accuracy and surface finish. Unlike casting, which often requires extensive machining to achieve the desired shape and surface quality, forged piston rods can be produced to near-net shape, minimizing material waste and reducing machining costs. The controlled deformation of the metal during forging eliminates internal voids and porosity commonly found in cast piston rods, resulting in a denser and more homogeneous microstructure. This enhanced material integrity translates to improved resistance against fatigue, corrosion, and wear, prolonging the service life of the shaft and reducing the risk of premature failure.

In addition to their mechanical properties and dimensional accuracy, forged piston rods offer versatility in material selection, allowing manufacturers to tailor the shaft’s composition to meet specific performance requirements. Various metals and alloys can be forged into piston rods, including carbon steel, alloy steel, stainless steel, titanium, and nickel-based alloys, each offering unique properties suited for different applications. Forged piston rods can also be customized with additional features such as keyways, threads, splines, and flanges, further enhancing their functionality and compatibility with mating components. Whether used in heavy-duty industrial machinery or precision instruments, forged piston rods provide engineers and designers with a reliable and cost-effective solution for transmitting power, supporting rotating elements, and maintaining mechanical integrity.

In summary, forged piston rods stand out for their exceptional strength, reliability, and versatility, making them indispensable components in a wide range of applications across industries. By harnessing the advantages of the forging process, manufacturers can produce piston rods that exhibit superior mechanical properties, dimensional accuracy, and material integrity compared to alternative manufacturing methods. Whether subjected to high loads, harsh environments, or demanding operating conditions, forged piston rods offer unmatched performance and longevity, ensuring the reliability and efficiency of critical machinery and equipment.

Post time: Apr-02-2024