Industry News

-

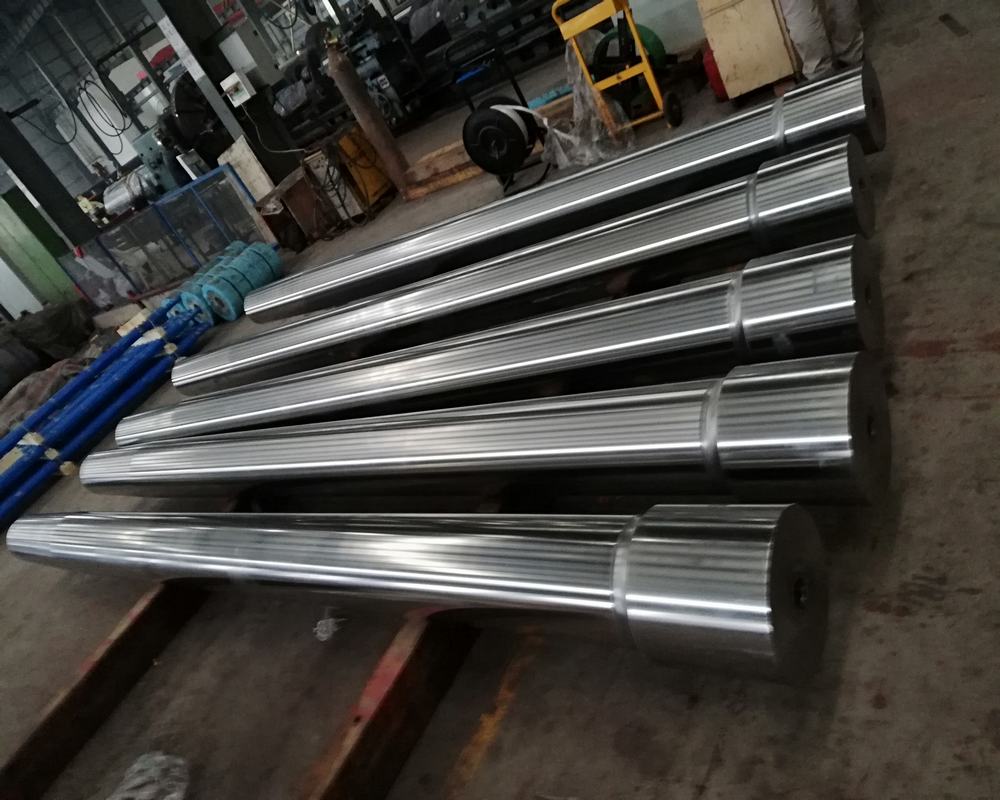

The Working Principle of a Pump Shaft

The pump shaft is a key component in centrifugal and rotary positive displacement pumps, transmitting torque from the prime mover to the pump’s impeller or moving parts. As the core of the pump rotor, it is equipped with impellers, shaft sleeves, bearings, and other components. Its main fun...Read more -

What is Mandrel Bar?

The Mandrel Bar is one of the important components in modern continuous rolling mills, and it plays a crucial role in the production process. The Mandrel Bar not only improves production efficiency, but also ensures high quality and consistency of the product. This article will introduce the work...Read more -

What Are Some of the Challenges Associated with Open Die Forging?

Open die forging, a traditional metalworking process, plays a vital role in shaping metal components for various industries. Despite its effectiveness, this forging method comes with its set of challenges that manufacturers need to overcome. In this article, we’ll explore some of the signif...Read more -

Can Open Die Forging Be Used for Both Small and Large Parts?

Open die forging is a versatile metalworking process known for its ability to shape metal into various forms. But can it be effectively used for both small and large parts? In this article, we’ll explore the versatility of open die forging and how it caters to the production needs of both s...Read more -

The Future of Forged Components: The Role of Aerospace and Defense

In the dynamic landscape of manufacturing, the demand for forged components is poised for significant growth in the coming decade. Among the various sectors driving this expansion, Aerospace and Defense stand out as key catalysts for the industry’s evolution. The Aerospace and Defens...Read more -

Exploring the Characteristics and Applications of H13 Tool Steel

H13 tool steel, a versatile and widely used material in the manufacturing industry, holds a prominent position due to its exceptional combination of properties and suitability for various applications. This article delves into the characteristics, properties, and applications of H13 tool steel, s...Read more -

What are the advantages of forging piston rods?

Forged piston rods are renowned for their superior strength and reliability, making them a preferred choice in various industries. One of the primary advantages of forged piston rods lies in the inherent grain structure resulting from the forging process. Unlike cast or machined piston rods, whic...Read more -

How to evaluate the quality of forgings?

Evaluating the quality of forgings involves assessing several key aspects to ensure that the final product meets the required standards and specifications. Here are some common methods used to evaluate forged components: Dimensional Accuracy: One of the primary indicators of forging qualit...Read more -

The Importance of Heat Treatment for Shafts’ Strength and Durability

Shafts are critical components in various mechanical systems, bearing the weight and transmitting the power of vehicles or machinery. To enhance their strength and durability, post-processing heat treatments are often employed. These procedures involve heating the Shafts to specific temperatures ...Read more -

The Importance of Chromium Content in Stainless Steel

Stainless steel is renowned for its durability, corrosion resistance, and aesthetic appeal. However, not all steel can claim the prestigious “stainless” prefix. One crucial element that determines whether steel qualifies as stainless is chromium content. Chromium plays a pivota...Read more -

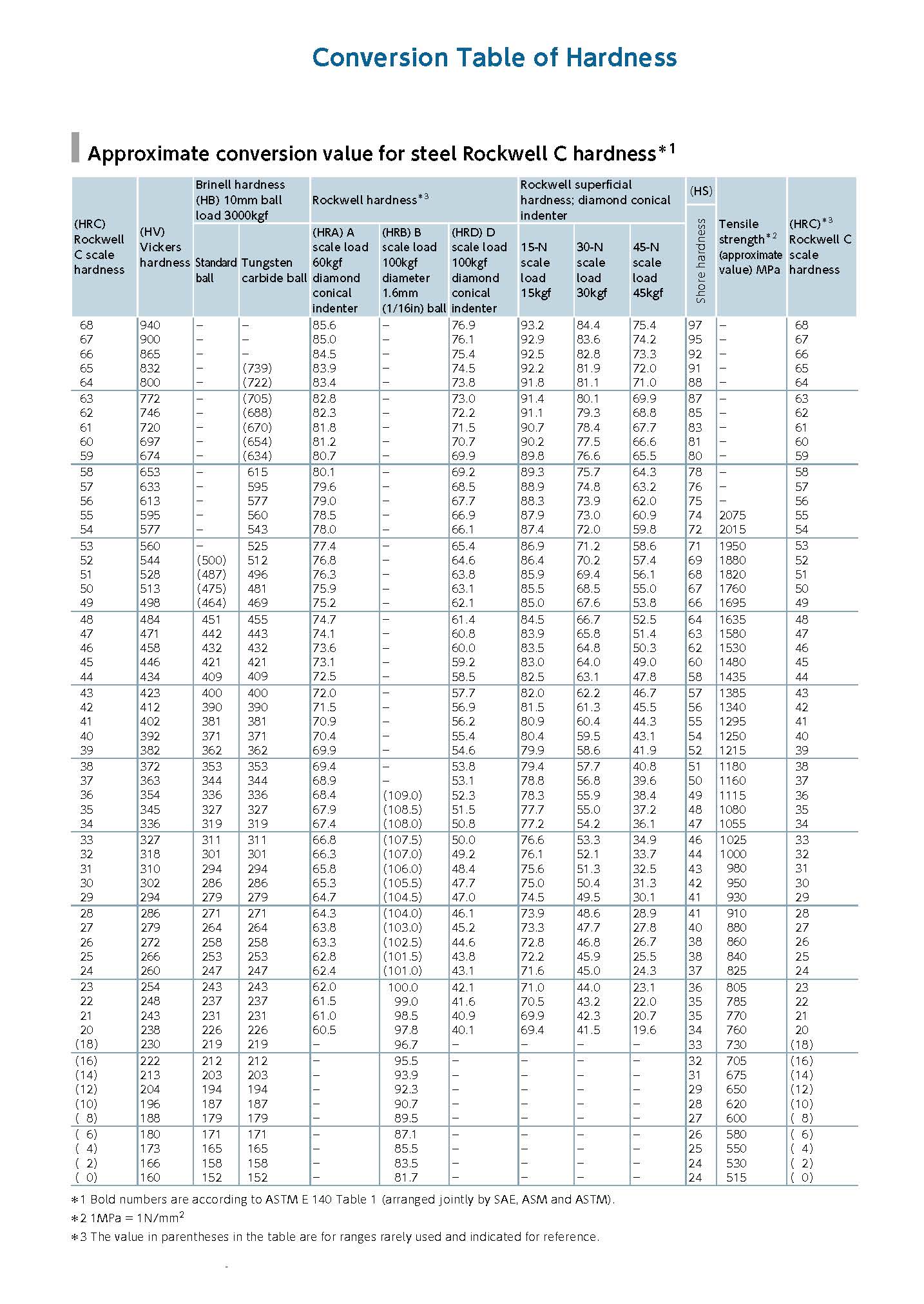

Conversion Table of Hardness

Read more -

What is a Forged Shaft?

A forged shaft is a crucial component used in various industrial applications, known for its strength, durability, and resilience. This type of shaft is manufactured through a process called forging, where metal is shaped by applying compressive forces. Let’s delve deeper into the character...Read more