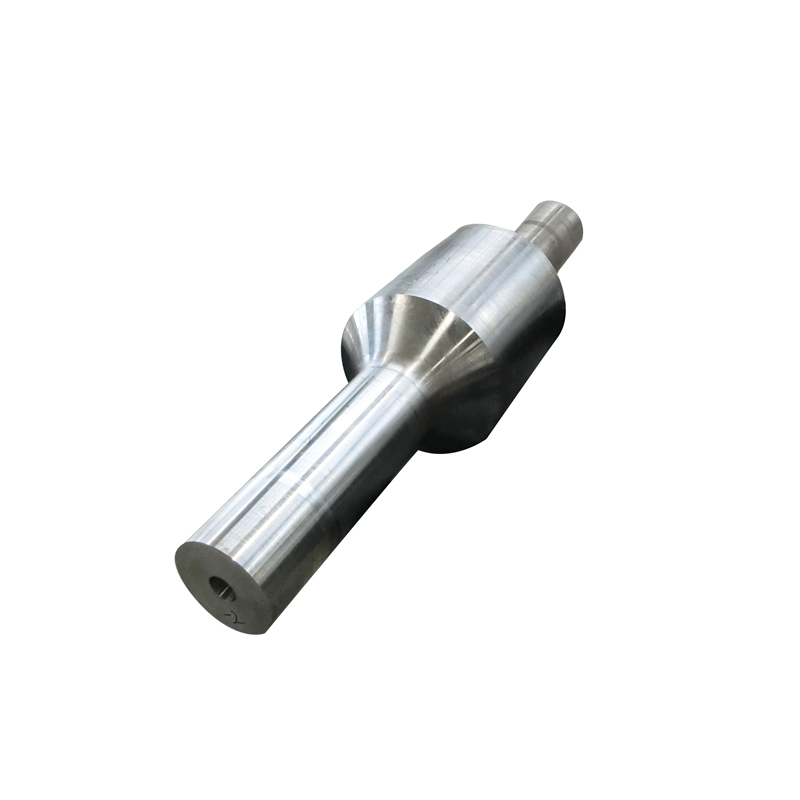

Retained Mandrel for Production ofSeamless Pipe

Our Advantages

20-year plus experience for manufacturing;

15-year plus experience for serving top oil equipment company;

On-site quality supervision and inspection.;

100% NDT for all bodies.

Shop self-check + WELONG’s double check, and third-party inspection (if required.)

Product Description

WELONG’s retained mandrel is specifically designed for the production of large-diameter seamless steel pipes in steel plants. As an essential component in the seamless pipe rolling process, the retained mandrel operates under extremely harsh conditions. It endures significant and complex tensile forces, as well as compressive contact stress and high-temperature thermal fatigue stresses during the rolling process. Consequently, the retained mandrel demands high standards in terms of the steel’s chemical composition, mechanical properties, non-metallic inclusions, grain size, microstructure, ultrasonic testing, dimensional accuracy, and surface roughness.

With 20 years of manufacturing experience, WELONG has established itself as a trusted provider of retained mandrels. The product name “WELONG’s retained mandrel” represents our commitment to excellence and innovation in this field. Our extensive industry knowledge and expertise allow us to uphold strict quality control measures throughout the manufacturing process. We ensure that each retained mandrel meets international standards, guaranteeing exceptional performance and long service life.

At WELONG, we recognize the importance of customer satisfaction. That’s why we not only focus on delivering top-notch products but also provide outstanding after-sales service. Our dedicated team is readily available to assist customers with any inquiries or concerns they may have. We prioritize building long-term relationships with our clients by addressing their needs promptly and effectively.

In addition to our superior product quality and attentive customer service, WELONG’s retained mandrel stands out for its utilization of H13 as the primary material. This choice ensures optimal strength, toughness, and resistance to thermal fatigue, further enhancing the performance and reliability of our retained mandrels.

In conclusion, WELONG’s retained mandrel is the result of two decades of manufacturing expertise, stringent quality control practices, and a commitment to exceptional customer service. We take pride in our ability to produce retained mandrels that meet international standards, while consistently delivering reliable and long-lasting performance.

Customized Service

Standard material grade

Customized material grade-differs in chemical and mechanical property

Customized Shape

Customized marking and package

Multiple payment term: T/T, LC, etc

Production Process

Order Confirmation in 1-2 days

Engineering

Production Planning

Raw Material Preparing

Incoming Material Inspection

Rough Machining

Heat Treatment

Mechanical Property Test

Finish turning

Final Inspection

Painting

Package & Logistic

Quality Control

5-times UT

Third Party Inspection

Good Service

Endurable products & Stable price.

Supply multiple inspections, UT, MT, X-ray, etc

Always react to customer’s urgent need.

Customized logo and package.

Optimize customer design & solutions.

Prefer to suggest more options than say no to customers.

Help customer group delivery in the whole China.

Less empiricism, more learning with open mind.

Online meeting freely via Teams, Zooms, Whatsapp, Wechat, etc

Customers

Delivery

20-years experiences with forwarders

Multiple shipping: Air transit/Sea shipping/Courier/etc

Arrange reliable and direct vessel within 1 week

Can cooperate on FOB/CIF/DAP/DDU, etc

Complete shipping documents for customs clearance