Rotary Reamer

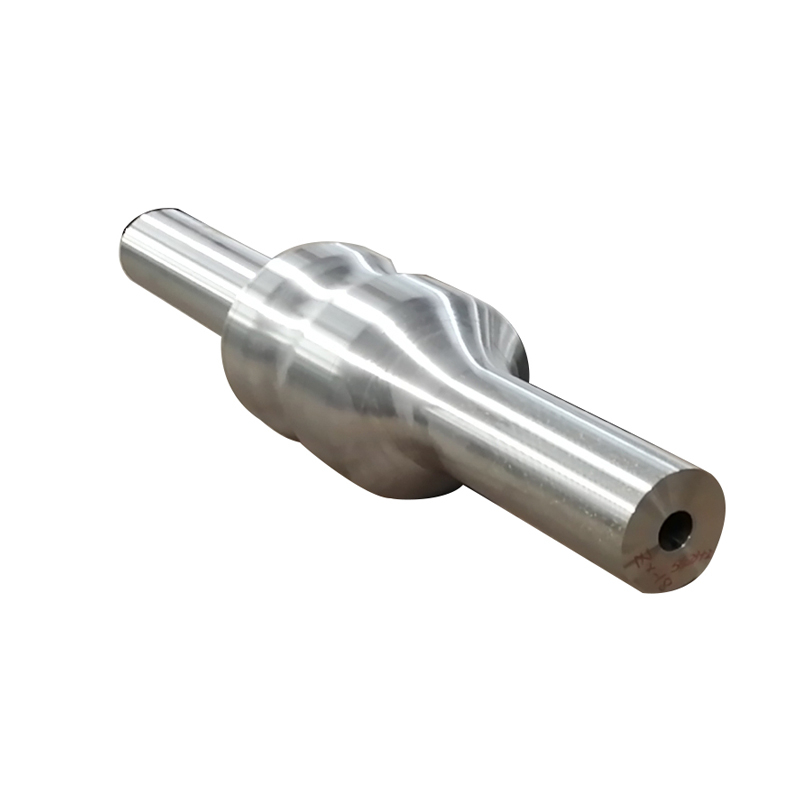

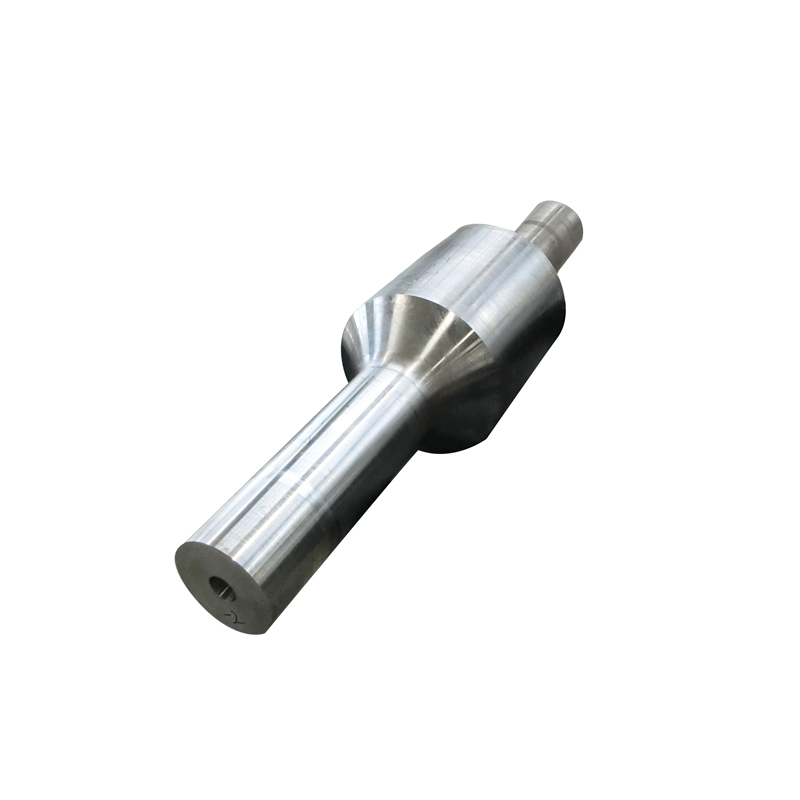

Roller Cutter Types

Hard Formation

Medium to Hard Formation

Soft Formation

Our Advantages

20-year plus experience for manufacturing;

15-year plus experience for serving top oil equipment company;

On-site quality supervision and inspection.;

For the same bodies of each heat treatment furnace batch, at least two bodies with their prolongation for mechanical performance test.

100% NDT for all bodies.

Shop self-check + WELONG’s double check, and third-party inspection (if required.)

|

Model |

Connection |

Hole Size |

Fishing Neck |

ID |

OAL |

Blade Length |

Roller Qty |

|

WLRR42 |

8-5/8 REG BOX x Pin |

42” |

11” |

3” |

118-130” |

24” |

3 |

|

WLRR36 |

7-5/8 REG BOX x Pin |

36” |

9.5” |

3” |

110-120” |

22” |

3 |

|

WLRR28 |

7-5/8 REG BOX x Pin |

28” |

9.5” |

3” |

100-110” |

20” |

3 |

|

WLRR26 |

7-5/8 REG BOX x Pin |

26” |

9.5” |

3” |

100-110” |

20” |

3 |

|

WLRR24 |

7-5/8 REG BOX x Pin |

24” |

9.5” |

3” |

100-110” |

20” |

3 |

|

WLRR22 |

7-5/8 REG BOX x Pin |

22” |

9.5” |

3” |

100-110” |

20” |

3 |

|

WLRR17 1/2 |

7-5/8 REG BOX x Pin |

17 1/2” |

9.5” |

3” |

90-100” |

18” |

3 |

|

WLRR16 |

7-5/8 REG BOX x Pin |

16” |

9.5” |

3” |

90-100” |

18” |

3 |

|

WLRR12 1/2 |

6-5/8 REG BOX x Pin |

12 1/2” |

8” |

2 13/16” |

79-90” |

18” |

3 |

|

WLRR12 1/4 |

7-5/8 REG BOX x Pin |

12 1/4” |

8" |

2 13/16” |

79-90” |

18” |

3 |

|

WLRR8 1/2 |

4 1/2 IF BOX x Pin |

8 1/2” |

6 3/4” |

2 13/16” |

65-72” |

16” |

3 |

|

WLRR6 |

3-1/2 IF BOX x Pin |

6” |

4 3/4” |

2 1/4” |

60-66” |

16” |

3 |

Product Description

The primary function of WELONG's roller reamer is to enlarge the borehole during well drilling operations. This is achieved by cutting through various earth formations to achieve the desired size, which may be necessary when the drill bit becomes under-gauged due to wear.

We understand that different drilling conditions demand different tools. That's why WELONG offers a range of roller cutter types to cater to various formation types: Hard Formation, Medium to Hard Formation, and Soft Formation. Our roller reamers are available in hole sizes ranging from 6" to 42", providing versatility to suit different project requirements.

At WELONG, we prioritize quality and reliability. All the materials used in the production of our roller reamers come from reputable steel mills. The steel ingots undergo electric furnace smelting and vacuum degassing processes to ensure superior quality. Forging is carried out using hydraulic or water presses, with a minimum forging ratio of 3:1. The resulting product exhibits excellent grain size of 5 or better, and cleanliness, meeting ASTM E45 standards for average inclusion content.

To guarantee structural integrity, our roller reamers undergo thorough ultrasonic testing following the flat-bottom hole procedure specified in ASTM A587. Both direct and oblique inspections are performed to identify any potential flaws. Furthermore, our roller reamers adhere strictly to the API 7-1 standard, ensuring compliance with industry regulations.

Before shipment, WELONG's roller reamers undergo meticulous surface cleaning. After surface preparation with a cleaning agent, they are left to dry completely before being coated with rust preventive oil. Each roller reamer is carefully wrapped in white plastic sheeting, followed by tightly secured green fabric wrapping to prevent any leakage or damage during transportation. To ensure maximum protection during long-distance shipping, our roller reamers are packaged using sturdy iron frames.

WELONG takes pride in not only delivering high-quality products but also providing excellent customer service. Our team is committed to meeting and exceeding customer expectations, offering comprehensive after-sales support to ensure complete satisfaction.

Choose WELONG's roller reamer for your drilling operations and experience the perfect blend of precision, durability, and exemplary service.

Customized Service

Standard material grade

Customized material grade-differs in chemical and mechanical property

Customized Shape

Customized marking and package

Multiple payment term: T/T, LC, etc

Production Process

Order Confirmation in 1-2 days

Engineering

Production Planning

Raw Material Preparing

Incoming Material Inspection

Rough Machining

Heat Treatment

Mechanical Property Test

Finish turning

Final Inspection

Painting

Package & Logistic

Quality Control

5-times UT

Third Party Inspection

Good Service

Endurable products & Stable price.

Supply multiple inspections, UT, MT, X-ray, etc

Always react to customer’s urgent need.

Customized logo and package.

Optimize customer design & solutions.

Prefer to suggest more options than say no to customers.

Help customer group delivery in the whole China.

Less empiricism, more learning with open mind.

Online meeting freely via Teams, Zooms, Whatsapp, Wechat, etc

Customers

Delivery

20-years experiences with forwarders

Multiple shipping: Air transit/Sea shipping/Courier/etc

Arrange reliable and direct vessel within 1 week

Can cooperate on FOB/CIF/DAP/DDU, etc

Complete shipping documents for customs clearance